As the calendar turns, it brings a natural moment for reflection and intention. Many of us make resolutions to hustle harder or achieve more, but what if this year’s goal was different? What if the objective was not to add more, but to find peace within what you already have? This year offers a chance to embrace calm, slow down, and cultivate a sense of inner tranquility. A powerful and beautiful way to embark on this journey is by incorporating a symbol of serenity into your daily life: the Japanese kimono.

This traditional garment is more than just clothing; it is a wearable piece of art that encourages mindfulness and peace. In this post, we will explore how a kimono or yukata can become an essential part of your routine for relaxation and renewal. We will discuss its history as a garment of grace and how you can use it to enhance practices like meditation, quiet reflection, and letting go of negative energy. Prepare to discover how a new kimono can lead to a new, more centered you.

The Kimono: A Symbol of Tranquility and Grace

The kimono has a rich history that stretches back over a thousand years in Japan. Its straight-seamed, T-shaped design has remained largely unchanged, a testament to its timeless elegance. Traditionally, the act of putting on a kimono is a deliberate and mindful process, a ritual in itself that encourages a slower, more intentional state of being. The very structure of the garment guides the wearer into a posture of grace and poise.

While formal kimonos are reserved for special occasions, the more casual yukata—a lighter, cotton version—offers an accessible way to experience this tradition daily. Wearing a yukata or a simple silk kimono at home transforms your personal space into a sanctuary. The soft fabric against your skin and the gentle rustle as you move serve as subtle reminders to breathe deeply and move with purpose. It signals to your mind and body that it is time to transition from the busyness of the day to a state of quiet and rest.

Creating a Ritual for Inner Peace

Integrating a kimono into your daily life can help establish powerful rituals for mental and spiritual well-being. Think of it as a uniform for your inner self, a garment you put on to connect with a calmer state of mind.

Enhancing Meditation and Mindfulness

For those who practice meditation, a kimono can significantly deepen the experience. The loose, comfortable fit allows you to sit without restriction, helping you focus on your breath rather than physical discomfort. The act of putting on your robe before you begin can serve as a trigger, signaling to your brain that it’s time to enter a meditative state.

Imagine starting your morning not by rushing to check your phone, but by gently wrapping yourself in a beautiful yukata. You find a quiet corner, sit comfortably, and close your eyes. The garment becomes part of the peaceful environment you are creating, helping you shut out distractions and turn your focus inward. This simple practice sets a tone of calm that can carry you through the rest of your day.

A Companion for Prayer and Mantras

Prayer, chanting, and reciting mantras are ancient practices for focusing the mind and connecting with a higher spiritual plane. These activities benefit from a dedicated space and a prepared mindset. Donning a kimono before you begin can help you transition from the mundane to the sacred. It’s a physical act that symbolizes your intention to be present and reverent.

The clean lines and elegant flow of the robe can help you feel more centered and composed. As you engage in your spiritual practice, the kimono serves as a gentle embrace, providing a sense of comfort and security. It helps to create a cocoon of peace, allowing your words and thoughts to flow more freely without the interference of outside stress.

The Art of Simply Unwinding

You don’t need a formal practice to benefit from the calming influence of a kimono. Sometimes, the most profound act of self-care is simply allowing yourself to unwind. After a long day, changing out of your work clothes and into a soft yukata is a powerful act of release. It marks a clear boundary between your public, professional life and your private, personal time for rest.

Wear it while you sip a cup of herbal tea, read a book, listen to calming music, or simply sit and gaze out the window. This simple change of attire encourages you to let go of the day’s tensions. It’s an invitation to release negative thoughts and energy that may have accumulated. The physical comfort of the robe promotes mental and emotional relaxation, helping you recharge and reset.

A New Kimono for a New You

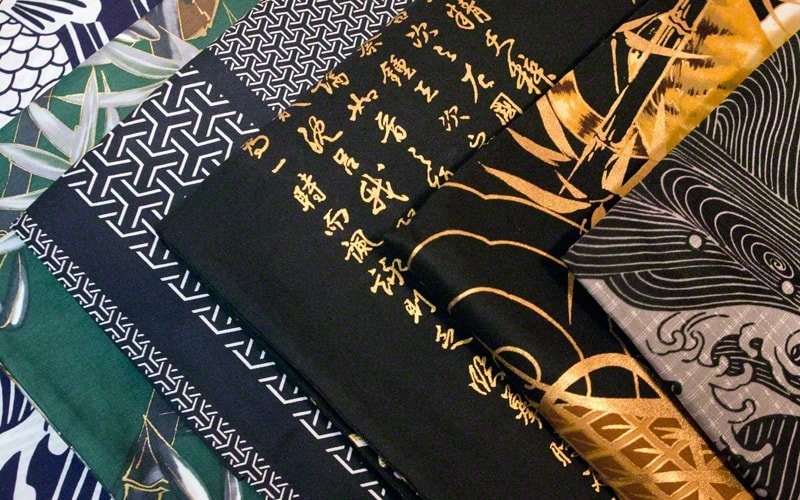

The new year is a perfect time to invest in yourself and your well-being. Choosing a new kimono is a beautiful and tangible way to commit to a more peaceful and centered life. It’s a personal choice—select a color, pattern, and fabric that speaks to you and makes you feel serene. Perhaps a design with flowing water to symbolize emotional release, or one with cherry blossoms to represent renewal and the beauty of the present moment.

Let this garment be a reminder of your intention for the year ahead. Every time you wear it, you are reaffirming your commitment to finding calm, practicing mindfulness, and nurturing your inner peace. It’s more than just a robe; it’s a tool for transformation.

As you move into this new year, consider making space for quiet moments and intentional relaxation. Let a kimono be your partner on this journey, a symbol of the grace and tranquility you wish to cultivate. Embrace the opportunity to slow down, breathe, and connect with yourself on a deeper level. A new kimono can be the first step toward a renewed and more peaceful you.